Way better.

Way better.# # #

# # #

PDI+ certification? We don't need no stinking PDI+ certification.

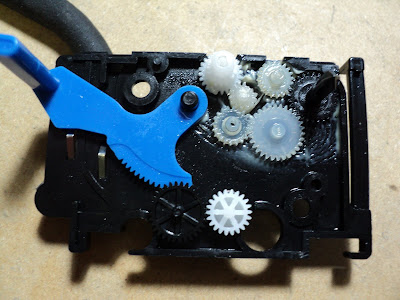

2) Gear Case

2) Gear Case The small gear that shuttles back and forth to maintain unidirectional output has lost two teeth. The only reason I can think of for that to happen is that a ribbon cartridge may have seized while operating.

The small gear that shuttles back and forth to maintain unidirectional output has lost two teeth. The only reason I can think of for that to happen is that a ribbon cartridge may have seized while operating. The third tubing length can just barely be gotten slipped on. Make sure you've fully shrunk the first two tubing lengths, and the third length will go on.

The third tubing length can just barely be gotten slipped on. Make sure you've fully shrunk the first two tubing lengths, and the third length will go on. 7) Pickup Assembly

7) Pickup Assembly And here it is stuck in its energized state, in the absence of any applied energy.

And here it is stuck in its energized state, in the absence of any applied energy. On the solenoid's frame, there's a tiny rectangle of foam rubber adhered with pressure-sensitive adhesive; it's there to quiet the solenoid's operation. The foam rubber deteriorates with age, and the adhesive bleeds through. The result is a sticky solenoid that will cause the clutch it's controlling to double-cycle. That can result in some quite mystifying symptoms. Here's a view of the ruined foam rubber.

On the solenoid's frame, there's a tiny rectangle of foam rubber adhered with pressure-sensitive adhesive; it's there to quiet the solenoid's operation. The foam rubber deteriorates with age, and the adhesive bleeds through. The result is a sticky solenoid that will cause the clutch it's controlling to double-cycle. That can result in some quite mystifying symptoms. Here's a view of the ruined foam rubber. HP doesn't break out this solenoid as a service replacement part, but it's not at all difficult to get a sticky solenoid working properly.

HP doesn't break out this solenoid as a service replacement part, but it's not at all difficult to get a sticky solenoid working properly. The solenoid will work fine, but it won't be as quiet as it was. It will make an audible, though not objectionable, muffled 'click' every time it's energized.

The solenoid will work fine, but it won't be as quiet as it was. It will make an audible, though not objectionable, muffled 'click' every time it's energized. The assembly resides on the inboard side of the right side vertical chassis member, where it transmits rotation from the main drivetrain to the fuser when the toner cartridge access door is closed.

The assembly resides on the inboard side of the right side vertical chassis member, where it transmits rotation from the main drivetrain to the fuser when the toner cartridge access door is closed. The white gear is in constant mesh with the printer's drivetrain, and is the clutch-controlled input to the feed shaft and the black gear.

The white gear is in constant mesh with the printer's drivetrain, and is the clutch-controlled input to the feed shaft and the black gear. Those two outermost rollers are completely free-turning on their shaft. Unless they're out of place like the one's pictured, visual inspection won't reveal the condition. You have to take the assembly out of the machine.

Those two outermost rollers are completely free-turning on their shaft. Unless they're out of place like the one's pictured, visual inspection won't reveal the condition. You have to take the assembly out of the machine. Note the registration gate barriers. The new barriers have square-cornered ends. The old barriers are worn away to an angle. That amount of wear would render the skew-correction function inoperative.

Note the registration gate barriers. The new barriers have square-cornered ends. The old barriers are worn away to an angle. That amount of wear would render the skew-correction function inoperative. Above is the 40X0 part. Below is the 4100 part. Note the cut/punched raised portion of the flap near the left side end of the 4100 part. That provides clearance for a sensor toggle that's not present in the 40X0.

Above is the 40X0 part. Below is the 4100 part. Note the cut/punched raised portion of the flap near the left side end of the 4100 part. That provides clearance for a sensor toggle that's not present in the 40X0. And here it is opened up for clearing a jam. (The difference is subtle -- the position of the green lever is the key to seeing it.)

And here it is opened up for clearing a jam. (The difference is subtle -- the position of the green lever is the key to seeing it.) The paper path above the tractor is opened up slightly, the tractors are lowered and disengaged from the drive train, and a switch at the left side of the chassis (the 'OC switch unit') has been opened. The switch is the sensor for open/closed status of the front tractor.

The paper path above the tractor is opened up slightly, the tractors are lowered and disengaged from the drive train, and a switch at the left side of the chassis (the 'OC switch unit') has been opened. The switch is the sensor for open/closed status of the front tractor. 'PAPER OUT' is flashing, 'COUR 10' and 'Time PS' are lit. (The 'MENU 1' LED has no relevance to this.) The printer is inoperative. To recover from the alarm, latch the tractor back in its normal operating position and power off and back on.

'PAPER OUT' is flashing, 'COUR 10' and 'Time PS' are lit. (The 'MENU 1' LED has no relevance to this.) The printer is inoperative. To recover from the alarm, latch the tractor back in its normal operating position and power off and back on. Note the disengaged gear that's below and to the right of the switch; that's the tractor drive gear. It's normally in mesh with the gear above it when the tractor is latched up in place.

Note the disengaged gear that's below and to the right of the switch; that's the tractor drive gear. It's normally in mesh with the gear above it when the tractor is latched up in place. A switch that develops high contact resistance with age will give false Jam Lever Alarms. A service replacement switch is P/N CA02464-F365. The switch's two-conductor cable plugs into connector 'CNMUOC' on the Connector PCA.

A switch that develops high contact resistance with age will give false Jam Lever Alarms. A service replacement switch is P/N CA02464-F365. The switch's two-conductor cable plugs into connector 'CNMUOC' on the Connector PCA. The switch is actuated indirectly by means of a pivoted paddle that's quite strongly spring loaded. 'Easiest way to cheat it is to clamp a small set of Vise-Grips on the upper corner of the switch's mounting bracket, just above the actuating paddle, like so.

The switch is actuated indirectly by means of a pivoted paddle that's quite strongly spring loaded. 'Easiest way to cheat it is to clamp a small set of Vise-Grips on the upper corner of the switch's mounting bracket, just above the actuating paddle, like so. Clamp on the Vise-Grips good and tight so they won't tumble on you while the machine is running.

Clamp on the Vise-Grips good and tight so they won't tumble on you while the machine is running. Lash a suitable magnet in place with rubber bands. (The magnet in the photo is from a cabinet door latch.) The sensors are sensitive to magnetic polarity, so you have to experiment a bit to find the magnet orientation that works.

Lash a suitable magnet in place with rubber bands. (The magnet in the photo is from a cabinet door latch.) The sensors are sensitive to magnetic polarity, so you have to experiment a bit to find the magnet orientation that works. I imagine what happened here is that the screw had been installed only finger tight, and the resulting electrical connection was good enough to work, but resistive enough that it heated up something fierce. Eventually, it got hot enough that it effectively spot-welded itself together and continued to work. I had to peel the lamp's terminal off with a knife blade.

I imagine what happened here is that the screw had been installed only finger tight, and the resulting electrical connection was good enough to work, but resistive enough that it heated up something fierce. Eventually, it got hot enough that it effectively spot-welded itself together and continued to work. I had to peel the lamp's terminal off with a knife blade. A 7/64" drill in the drill press took care of the screw remnant, and left me with a hole just a little undersize for an M3 screw. I ran an M3 threading tap through it to create a vestigal thread, and rounded up the bits I'd need to refasten the terminal. Here's a view of the repair almost done.

A 7/64" drill in the drill press took care of the screw remnant, and left me with a hole just a little undersize for an M3 screw. I ran an M3 threading tap through it to create a vestigal thread, and rounded up the bits I'd need to refasten the terminal. Here's a view of the repair almost done. The terminal's been well scraped. A small diameter sanding drum in a hand grinder took care of the bubbled, bloated plastic by the terminal.

The terminal's been well scraped. A small diameter sanding drum in a hand grinder took care of the bubbled, bloated plastic by the terminal. That'll work fine.

That'll work fine. The unit is actually two sensors -- an EOF sensor and a 'hole count' sensor.

The unit is actually two sensors -- an EOF sensor and a 'hole count' sensor. Yikes! Four adjustment pots. That looks to me like a very good thing to stay away from.

Yikes! Four adjustment pots. That looks to me like a very good thing to stay away from. It's a reflective object sensor (ROS) that 'sees' the leading edge of the forms arrive as they're loading, and informs the Logic PCA so the paper can be positioned accordingly.

It's a reflective object sensor (ROS) that 'sees' the leading edge of the forms arrive as they're loading, and informs the Logic PCA so the paper can be positioned accordingly. (The "DC" on the connector stands for "Door Closed".) Be certain that you have the correct contact, the lower contact, pin 1. The centre contact is ground. The upper contact is the sensor's VCC supply (+5 VDC) -- shorting that one to ground might cause damage to the Logic PCA.

(The "DC" on the connector stands for "Door Closed".) Be certain that you have the correct contact, the lower contact, pin 1. The centre contact is ground. The upper contact is the sensor's VCC supply (+5 VDC) -- shorting that one to ground might cause damage to the Logic PCA. The sensor is sensitive to magnetic polarity, so you have to experiment a bit to find the magnet orientation that works.

The sensor is sensitive to magnetic polarity, so you have to experiment a bit to find the magnet orientation that works. A hairline fracture in the sensor PCA. Oki supplied a replacement under warranty.

A hairline fracture in the sensor PCA. Oki supplied a replacement under warranty. To remove a ribbon, you're supposed to tip the mask carrier toward the platen and pull it up off the posts, but it can be obstinate. Try too hard and you're liable to break the thing, like I did.

To remove a ribbon, you're supposed to tip the mask carrier toward the platen and pull it up off the posts, but it can be obstinate. Try too hard and you're liable to break the thing, like I did.

The good news is that even though the thing is broken, it still fits in place and works.

The good news is that even though the thing is broken, it still fits in place and works. I looked into this, and found an 'explanation' of sorts, though I remain a bit mystified as to why it was done. The following is verbatim from Lexmark's 4062-XXX Service Manual (pp. 3-73 & 3-74):

I looked into this, and found an 'explanation' of sorts, though I remain a bit mystified as to why it was done. The following is verbatim from Lexmark's 4062-XXX Service Manual (pp. 3-73 & 3-74): I performed the same test on a T640 fuser and on a T630 fuser, and they're all the same in this regard. It appears that with the introduction of the one-piece, torsion-spring sprung detac bar on the T630, the detac fingers were made not to contact the hot roller.

I performed the same test on a T640 fuser and on a T630 fuser, and they're all the same in this regard. It appears that with the introduction of the one-piece, torsion-spring sprung detac bar on the T630, the detac fingers were made not to contact the hot roller. We got a new redrive assembly from Lexmark, and the new one has a flat-spotted delivery exit roller as well. It appears that all E260d delivery exit rollers are likely to acquire flat spots.

We got a new redrive assembly from Lexmark, and the new one has a flat-spotted delivery exit roller as well. It appears that all E260d delivery exit rollers are likely to acquire flat spots. - Unplug the cable and free it from its restraints.

- Unplug the cable and free it from its restraints. 23) Right Side Ground Continuity Tab Contact

23) Right Side Ground Continuity Tab Contact One of the cartridge's contacts had gotten snagged and badly distorted. With that contact incapable of making to the cartridge, the printer couldn't know that that there was a cartridge in place.

One of the cartridge's contacts had gotten snagged and badly distorted. With that contact incapable of making to the cartridge, the printer couldn't know that that there was a cartridge in place. I got the contact out and pressed it onto a piece of 6mm diameter rod to make it easier to handle for reforming.

I got the contact out and pressed it onto a piece of 6mm diameter rod to make it easier to handle for reforming. The contact went back into the chassis ok, but I didn't like the way the contact's upper torsion coil fit on its post, so I added a threading screw and flat washer to retain it.

The contact went back into the chassis ok, but I didn't like the way the contact's upper torsion coil fit on its post, so I added a threading screw and flat washer to retain it. The post had a hole in its centre that I enlarged with a 3/32" drill -- that took a short M3 threading screw nicely.

The post had a hole in its centre that I enlarged with a 3/32" drill -- that took a short M3 threading screw nicely. The holes are sight holes, for confirming that the high voltage connections are properly made with the power supply in place. It's not much of a view that you get through those little holes, but it's enough that you can visually confirm the connections.

The holes are sight holes, for confirming that the high voltage connections are properly made with the power supply in place. It's not much of a view that you get through those little holes, but it's enough that you can visually confirm the connections.

Like the content? Help me keep it coming!

Donate any amount via PayPal and help support this blog.