To clear the NVRAM and restore the factory defaults, press and hold the following three keys while powering on:

- Right side of 'Menu'

- 'Select'

- 'Go'

The network setup is unaffected; only the printer menu settings are reset.

# # #

# # #

PDI+ certification? We don't need no stinking PDI+ certification.

The actuation interface was poorly designed. With long use, the end of the lever wears until it tends to wedge in place on top of the actuator protrusion and jam the drawer closed. The user yanks hard on the drawer to open it and the lever breaks. The tray is rendered inoperative because the outfeed pinch roller is no longer tensioned by a closed drawer -- the tray can no longer feed out paper reliably.

The actuation interface was poorly designed. With long use, the end of the lever wears until it tends to wedge in place on top of the actuator protrusion and jam the drawer closed. The user yanks hard on the drawer to open it and the lever breaks. The tray is rendered inoperative because the outfeed pinch roller is no longer tensioned by a closed drawer -- the tray can no longer feed out paper reliably.

What the screw head does is it provides a lever actuation surface that deflects the lever without ever getting underneath its end. A drawer with this modification done to it will never wedge under a lever and break it.

What the screw head does is it provides a lever actuation surface that deflects the lever without ever getting underneath its end. A drawer with this modification done to it will never wedge under a lever and break it. The light spring that extends down the upper side of the autocompensator arm is a counterbalance spring. It's there to limit the pressure the pickup tires can exert when they're turning, so that multiple pickups don't occur.

The light spring that extends down the upper side of the autocompensator arm is a counterbalance spring. It's there to limit the pressure the pickup tires can exert when they're turning, so that multiple pickups don't occur. That minimizes the spring's counterbalancing effect, maximizing traction. (On the T640 and T650 integral trays, the clip has been deleted; there's a series of holes along the top of the arm that provide the same adjustability.)

That minimizes the spring's counterbalancing effect, maximizing traction. (On the T640 and T650 integral trays, the clip has been deleted; there's a series of holes along the top of the arm that provide the same adjustability.)

If you examine the threads closely, you'll see that the threads are double helices, aka 'two-start' threads. I suspect that there's a limitation inherent to the screws' manufacturing process, because the threads are never perfectly symmetrical and uniform.

If you examine the threads closely, you'll see that the threads are double helices, aka 'two-start' threads. I suspect that there's a limitation inherent to the screws' manufacturing process, because the threads are never perfectly symmetrical and uniform. The method for removing and replacing it is a bit odd, but it does work and nothing ever breaks, even though it seems at times that something might.

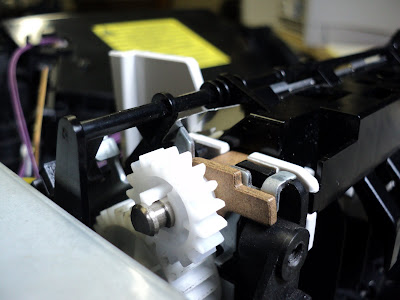

The method for removing and replacing it is a bit odd, but it does work and nothing ever breaks, even though it seems at times that something might. Note the thrust washer. Printers that have an add-on tray installed experience a constant upward thrust on the gear. Prior to the addition of the thrust washer, the gears would tend to wear quite badly where they rode in the upper bearing. The gear would keep moving upward until it would lose mesh. When installing a replacement gear, grease the upper end of it liberally.

Note the thrust washer. Printers that have an add-on tray installed experience a constant upward thrust on the gear. Prior to the addition of the thrust washer, the gears would tend to wear quite badly where they rode in the upper bearing. The gear would keep moving upward until it would lose mesh. When installing a replacement gear, grease the upper end of it liberally. Here's a view of it with the cover removed.

Here's a view of it with the cover removed. Metal fatigue, I guess. Where the reduced-diameter end of the roller meets the body of the roller, there's not a great deal of material. Here's a close-up of the broken-off end.

Metal fatigue, I guess. Where the reduced-diameter end of the roller meets the body of the roller, there's not a great deal of material. Here's a close-up of the broken-off end. The rest of the fuser was ok. Sometimes, a broken fuser roller will cause the thermal fuse to go open.

The rest of the fuser was ok. Sometimes, a broken fuser roller will cause the thermal fuse to go open. Slide on the new sleeve (black band at thermistor connector end), install the end cap, give the sleeve a turn or two and wipe away any squeeze-out that appears at the ends.

Slide on the new sleeve (black band at thermistor connector end), install the end cap, give the sleeve a turn or two and wipe away any squeeze-out that appears at the ends. The bronze bearing's axial position can seem a little ambiguous. It's supposed to go leftward against the brass washer and e-clip until the e-clip hits a stop. Here's how it should look.

The bronze bearing's axial position can seem a little ambiguous. It's supposed to go leftward against the brass washer and e-clip until the e-clip hits a stop. Here's how it should look.

At the very left is one end of a coated fuser roller from a Lexmark T640. Next to it is the bushing that goes on the end of the roller for thermal isolation. Next to the bushing is the ball bearing that fits over the bushing.

At the very left is one end of a coated fuser roller from a Lexmark T640. Next to it is the bushing that goes on the end of the roller for thermal isolation. Next to the bushing is the ball bearing that fits over the bushing. The claws become brittle with age, and break off and fall into the fuser -- not helpful. The cover pictured below has lost two of its six claws.

The claws become brittle with age, and break off and fall into the fuser -- not helpful. The cover pictured below has lost two of its six claws. Whenever you see this, take a pair of pliers and break off all the remaining claws. You'll save yourself some future aggravation.

Whenever you see this, take a pair of pliers and break off all the remaining claws. You'll save yourself some future aggravation. And here's a view of one of the two bearings that was at fault.

And here's a view of one of the two bearings that was at fault. This type of bearing is widely used in all makes and models of printers. Manufacturers love them because they're compact and inexpensive. They're also very durable, but they do require periodic attention, or they'll end up like the bearing shown above.

This type of bearing is widely used in all makes and models of printers. Manufacturers love them because they're compact and inexpensive. They're also very durable, but they do require periodic attention, or they'll end up like the bearing shown above.

18 AWG (0.0403" diameter) wire is substantial enough, yet relatively easy to form. Once you have the wire formed and in place, clean the item thoroughly with methyl hydrate, let it dry and apply CA adhesive so it wicks in everywhere between the copper wire and the plastic toggle. Take great care that the glue doesn't get away from you and foul the torsion spring or pivots. Leave the thing undisturbed for awhile for the glue to thoroughly harden.

18 AWG (0.0403" diameter) wire is substantial enough, yet relatively easy to form. Once you have the wire formed and in place, clean the item thoroughly with methyl hydrate, let it dry and apply CA adhesive so it wicks in everywhere between the copper wire and the plastic toggle. Take great care that the glue doesn't get away from you and foul the torsion spring or pivots. Leave the thing undisturbed for awhile for the glue to thoroughly harden. I've done enough of these that I've seen machines return to the shop after considerable service with one of these repairs; this repair method appears to hold up fine.

I've done enough of these that I've seen machines return to the shop after considerable service with one of these repairs; this repair method appears to hold up fine.

Like the content? Help me keep it coming!

Donate any amount via PayPal and help support this blog.